Specific introduction to the definition of hot rolled coil

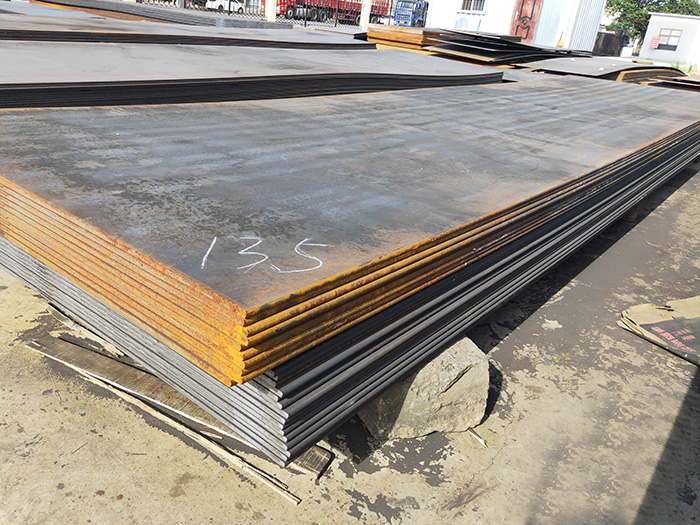

Ingots or billets are difficult to deform and process at room temperature. They are usually heated to 1100 ~ 1250 ℃ for rolling. This rolling process is called hot rolling. The temperature of hot rolled plate is high, so the deformation resistance is small, and large deformation can be achieved. Taking the rolling of steel plate as an example, the thickness of continuous casting slab is generally about 230mm, while after rough rolling and finish rolling, the final Z thickness is 1~20mm. At the same time, because the width thickness ratio of the steel plate is small, and the requirements for dimensional accuracy are relatively low, the shape problem is not easy to occur, and the convexity is mainly controlled. For the structure requirements, it is generally realized by controlled rolling and controlled cooling, that is, the microstructure and mechanical properties of the strip are controlled by controlling the start rolling temperature, final rolling temperature and crimp temperature of the finish rolling.