Talking about the advantages of hot rolling plate

With the different process parameters, the internal stress distribution is also different, which will appear in different directions of the vertical long open plate. Moreover, this bearing capacity is difficult to be weighed by ordinary strength index. Therefore, there will be great welding deformation when welding the split plate, which is difficult to adjust. Therefore, the parts with high requirements for appearance quality cannot use the split plate.

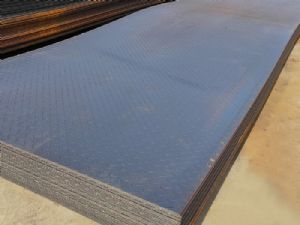

The open plate is the steel strip when the steel plant leaves the factory. It is a steel plate with a certain thickness and width rolled according to the user's requirements. The original plate is rolled into the size required by the national standard when it leaves the factory. The ordinary original plate has strict size, good performance and high price. The opening plate is relatively cheap, and the size is slightly different. The plate is 1.5-20mm thick and made of Q235 and Q345. It is mainly used for non compressed containers and storage tanks.

In the plate cutting industry, CNC cutting is one of the common methods. When we understand the cutting of medium and heavy plate, we should also understand its cutting method accordingly. When using CNC cutting, Chongqing medium and heavy plate sometimes deforms. Some control measures need to be taken. Let me tell you below!

First, oxygen of sufficient purity should be used. If the oxygen purity is not good, the cutting will become rough and affect the cutting quality. Secondly, after the cutting of multiple workpieces is completed, they should be steadily sorted out to effectively control the deformation.

Of course, when the thin plate slender parts are encountered, partial cooling shall be carried out, or the compensated cold shrinkage value shall be added in the programming according to the length, width and thickness of the cutting parts. In addition, the appearance of the cut and the medium plate should be straight, otherwise the cutting part will have the wrong size. It must be noted that parts that are easy to deform shall be placed in the middle of the medium plate, and sufficient space shall be reserved between parts. Select a reasonable cutting sequence and the correct direction of the piercing point to prevent the deformation of the cutting parts.